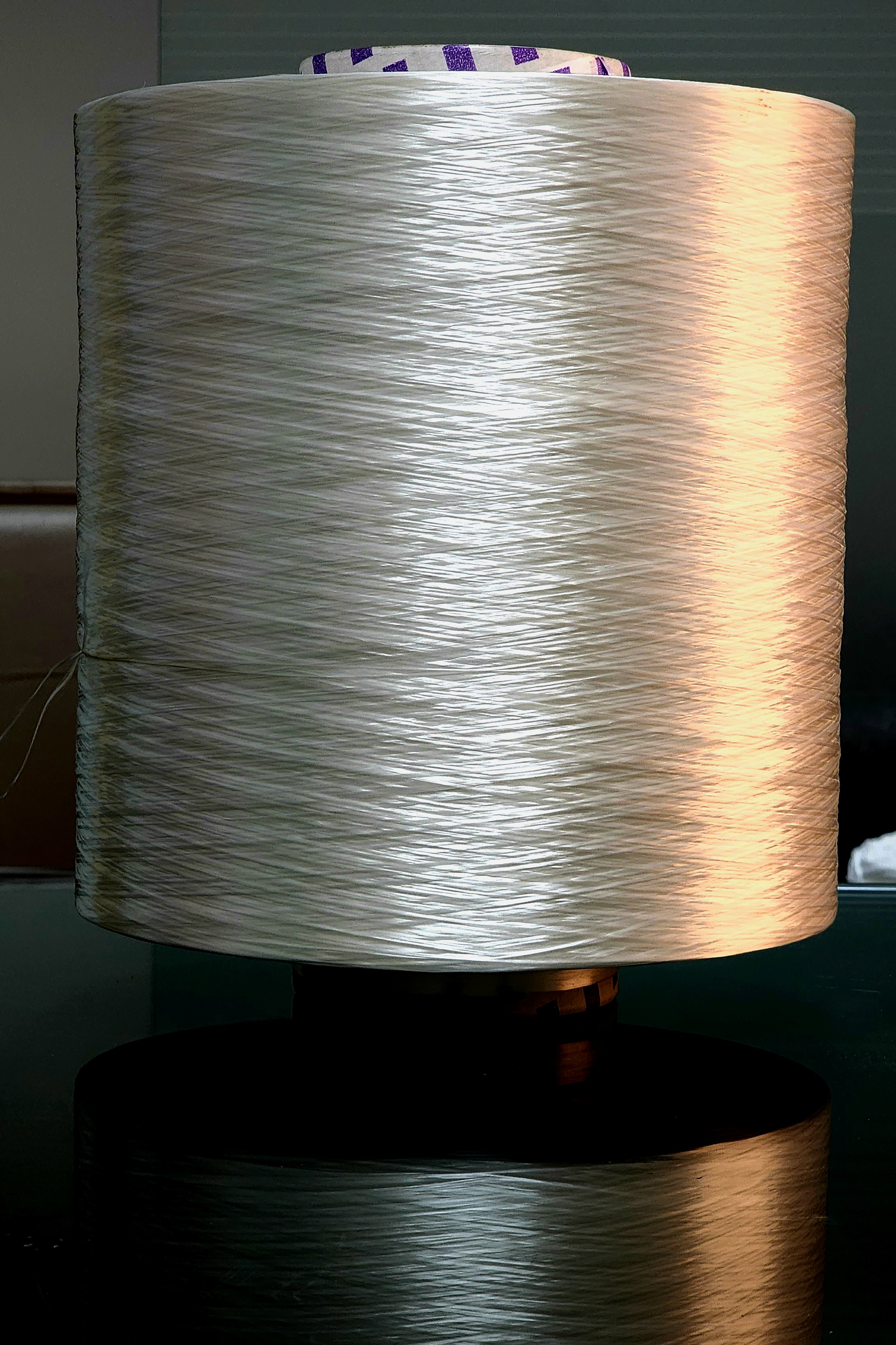

Parth Poly Coat Yarn Pvt Ltd. is a main exporter of High Tenacity Yarns in India and has been exporting world class quality high tenacity yarn to different nations over the globe creating its demand for quality products in Europe, Asia, Africa and America.

The filaments of the high tenacity yarn ideally have a cross-section having 5 to 8 vertices, possibly with indentation between the vertices. The cross-section of the filaments is ideally star-shaped. High Tenacity yarn is also available in various variations like typical shrinkage, low shrinkage and super low shrinkage depending on the suitable end-use. The high tenacity yarn is excellently suited for use in the manufacture of industrial fabrics, especially airbag fabrics

High tenacity yarns have been used in the manufacture of textiles, carpet and tarpaulin. In the manufacture of textile fabrics, for example, woven, knitted and crocheted fabrics and nonwovens from yarns containing synthetic polymer filaments, the most vital thought in the manufacture of these fabrics is the use of yarns with filaments having high tenacity and ensuring great foldability. The high tenacity yarn has high strength, durability and chemical resistance, and withstands extremely hot environment that can stress conventional multi-filaments to their performance limits.

Following are the most prominent uses of polyester yarn:

Fashion and footwear

Polyester yarn is utilized in the fashion industry for a long time. Its wrinkle resistant property makes it is highly preferred by the designers for special appearances, as it will make their outfit look classy and elegant.

Polyester is also used for footwear. Mostly for the purpose of winter footwear, as it absorbs more heat, hence providing you with comfort. While for the summer season, polyesters footwear is generally mixed along with other fabrics. Mostly polyester made shoes are preferred because of the durability of the fiber.

Sheets, duvet covers and sleeping bags

Polyester is helpful in the manufacturing of a number of sleeping bags. People highly use these bags use when they go on high altitudes for camping as it absorbs the heat and keeps them warm in cold regions.

As discussed earlier, polyester yarn uses static energy and becomes clingy. Therefore, it is used to make sheets and duvet covers, which remain fixed at their place for a long time. Moreover, its color does not fade away quickly.

Soft furnishings

A polyester yarn can be compressed to make soft furnishings. Some ultra-thin fibers are used by manufacturers, which give a smooth and soft surface to the polyester for an extended period.

The furniture made does not get affected in case of accidental spills. This is because the polyester yarn is mixed with other fabric in order smooth finishing protectio furniture.

Luggage and other kinds of bags

The polyester yarn has the 'no water absorb' property, thereby it's an excellent material for making bags, especially which carry a hefty load. The bags will not absorb water, especially if you are going to places which are near the sea or the ocean.

However, there is one condition to be applied. That is, it should not be mixed with wool for crease resistance. Also, the no wrinklingproperty makes polyester yarn an excellent fit for luggage, as it remains intact for years.

Making of duvets The

polyester yarn duvet will always keep you warm during the winter season. The yarn works as an insulator and does not allow the heat trapped around your body to leave the duet.

Thereby, the cold environment does not affect your body. Although, if you are using a polyester duvet along with a room heater, then it might make you feel uncomfortable after some time.

Sewing threads and textiles

Polyester yarn uses the 'fast dry technique, which refers to the policy of natural drying as compared to the other fabrics. Therefore, it is a good material to make sewing threads and various other textiles. Generally, it is mingled along with other fabrics to retain its properties.

Polyester is also capable of utilizing the features of different fabrics as well. With the innovation in technology and other factors, polyester is at times, combined with a plethora of fabrics. However, you can identify it reading the tags attached.

| Yarn Types & Applications | ||

|---|---|---|

| Type | Denier(D) | Applications |

| High Tenacity | 150-6000 | Sling, Tie-down, Strapping. Geotextile, Conveyorbelt fabric, Dipped Cord, Hose, Sunshade,Outdoor furniture. Rope, Net |

| Low Shrinkage | 250-3000 | Banner, Tarpaulin, Roofing, Membrane structure, Awning, Filter fabric, Sunshade, Outdoor furniture, Hose, Sewing thread |

| Low High Tenacity Shrinkage | 500-3000 | Banner, Tarpaulin, Roofing, Me mbrane structure, Awning, Filter fabric, Sunshade, Outdoor furniture, Hose, Sewing thread |

| Super Low Shrinkage | 500-2000 | Banner, Tarpaulin, Roofing, Me mbrane structure, Awning, Filter fabric, Sunshade, Outdoor furniture, Sewing thread |

| Abrasion Resistance | 500-2000 | Seat belt, Safety belt, Rope, Sling |

| Extra Low Shrinkage | 1000 | Superior quality banner, Superior quality tarpaulin, Superior quality membrane structure |

| High Tenacity High Shrinkage | 210-1000 | Sail Cloth |

| High Tenacity Low Elongation | 1000-6000 | Geotextile, Geogrid |

| High Tenacity Middle Shrinkage | 1000-6000 | Conveyor belt fabric, Soild Woven |

| Adhesive Activated | 500-6000 | Rubber reinforcement materials |

| Anti-wicking | 500-2000 | Superior quality banner, Roofing, Pool cover |

| Marine Finish Yarn | 1000-6000 | Mooring Rope |

| HMLS | 1000-2000 | Tire cord fabric, Conveyor belt fabric, Dipped cord, Superior quality geotextile |

| Airbag Yarn | 315-630 | Airbag |

| Coloured Yarn | 840-3000 | Sling, Tie-down, Strapping, Rope Luggade Fabric |

| Twisted Yarn | 250-15000 | Woven fabric, Canvas, Fire hose, Filter Fabric, Seat belt, Sewing thread |

| Multi-ply Yarn | 6000-30000 | Sling, Conveyor belt fabric, Geotextile, Rope |

| Multi-ply Twisted Yarn | 30000-120000 | Rope, Round Sling, Geoiextile |